Choose the Ideal Spa Cover

SPA cover Introduction

Choosing the ideal spa cover involves careful consideration of multiple factors to ensure optimal performance, longevity, safety, and cost-effectiveness. This guide will help you navigate through key selection criteria derived from material science and industry standards of the spa covers.

Core Insulation Material

Expanded Polystyrene (EPS)

· Pros: Lightweight, cost-effective, readily available. SPA cover provides initial insulation (R-value typically 12-14).

· Cons: Prone to water absorption, sagging under snow load, less durable (3-5 years lifespan). Susceptible to damage from chemicals and oils.

Extruded Polystyrene (XPS)

· Pros: SPA cover's Higher density (R-15 to R-20), resistant to water absorption, rigid, longer lifespan (5-8+ years).

· Cons: Heavier and more expensive than EPS, somewhat susceptible to chemical degradation over long periods.

Injection-Molded Polyurethane Foam (IMPA)

· Pros: Highest R-value per inch (R-25+), excellent structural integrity, resists sagging, highly durable (10+ years lifespan).

· Cons: Significantly higher initial cost, heaviest core option, requires robust hinge systems.

Vacuum-Insulated Panels (VIPs)

· Pros: Exceptional R-values (R-30+ per panel), extremely thin profile, lightweight.

· Cons: Extremely expensive, fragile, requires careful handling and robust protective casing, limited availability.

SPA cover Recommendation

· IMPA: Benchmark for performance and longevity.

· XPS: Good mid-range balance.

· Avoid EPS: Unless budget is the primary constraint.

· VIPs: Niche option.

Facing Material

Vinyl (PVC)

· Pros: Cost-effective, waterproof, wide range of colors and textures, easy to clean.

· Cons: Can crack, fade, and become brittle under prolonged UV exposure unless high-quality marine vinyl is used.

Reinforced Laminates

· Pros: Tear and puncture-resistant, excellent UV resistance, often carries extended warranties (10+ years).

· Cons: Higher cost than basic vinyl.

Thermoplastic Olefin (TPO)

· Pros: Highly UV resistant, flexible in cold temperatures, resistant to mold and mildew, environmentally friendlier than PVC.

· Cons: Higher cost, fewer color/texture options.

Recommendation

· Reinforced Laminates: Best balance of durability, UV protection, and value.

· High-Quality UV-stabilized Marine Vinyl: Good standard choice.

· TPO: Excels in extreme UV areas and for environmental priorities.

Vapor Barrier & Moisture Management

Critical Role

· Prevents moisture vapor from penetrating the core insulation, which is the primary killer of insulation R-value.

Common Barriers

· Aluminum Foil: Excellent vapor barrier, enhances radiant heat reflection.

· Metallized Film: Similar properties to foil but more flexible.

· Heavy-Duty Plastic Films: Effective if seams are perfect.

Seam Sealing

· Imperative. Requires robust adhesive tapes meticulously applied along all seams.

Recommendation

· Fully Encapsulated Core: In aluminum foil or metallized film barrier, essential for long-term performance.

Design & Structural Integrity

Tapered Design

· Essential for proper water runoff (standard is 4" to 2.5" taper).

Center Support

· Crucial for preventing sagging, especially with wider spas (7.5ft+).

Reinforced Corners & Edges

· High-stress areas should feature extra material layers or plastic/composite corner guards.

Hinge System

· Continuous/Piano Hinge: Most common, ensure thick, reinforced vinyl.

· Strap Hinges: Stronger, distributes stress well, better for heavy covers.

· Internal Cable Hinge: Extremely strong, invisible, but harder to repair.

Recommendation

· Tapered Design, Center Support, Reinforced Corners, Robust Hinge System: Non-negotiable for durability.

SPA cover Safety Features

Locking Mechanisms

· Slide Bolts: Simple, manual bolts securing the cover.

· Keyed Locks: Higher security.

· Spa Cover Clamps: Most secure option against wind and unauthorized access.

Weight Capacity

· Industry standard is a minimum of 65 lbs per square foot load capacity.

Wind Straps

· Crucial in exposed locations, prevents wind uplift.

Recommendation

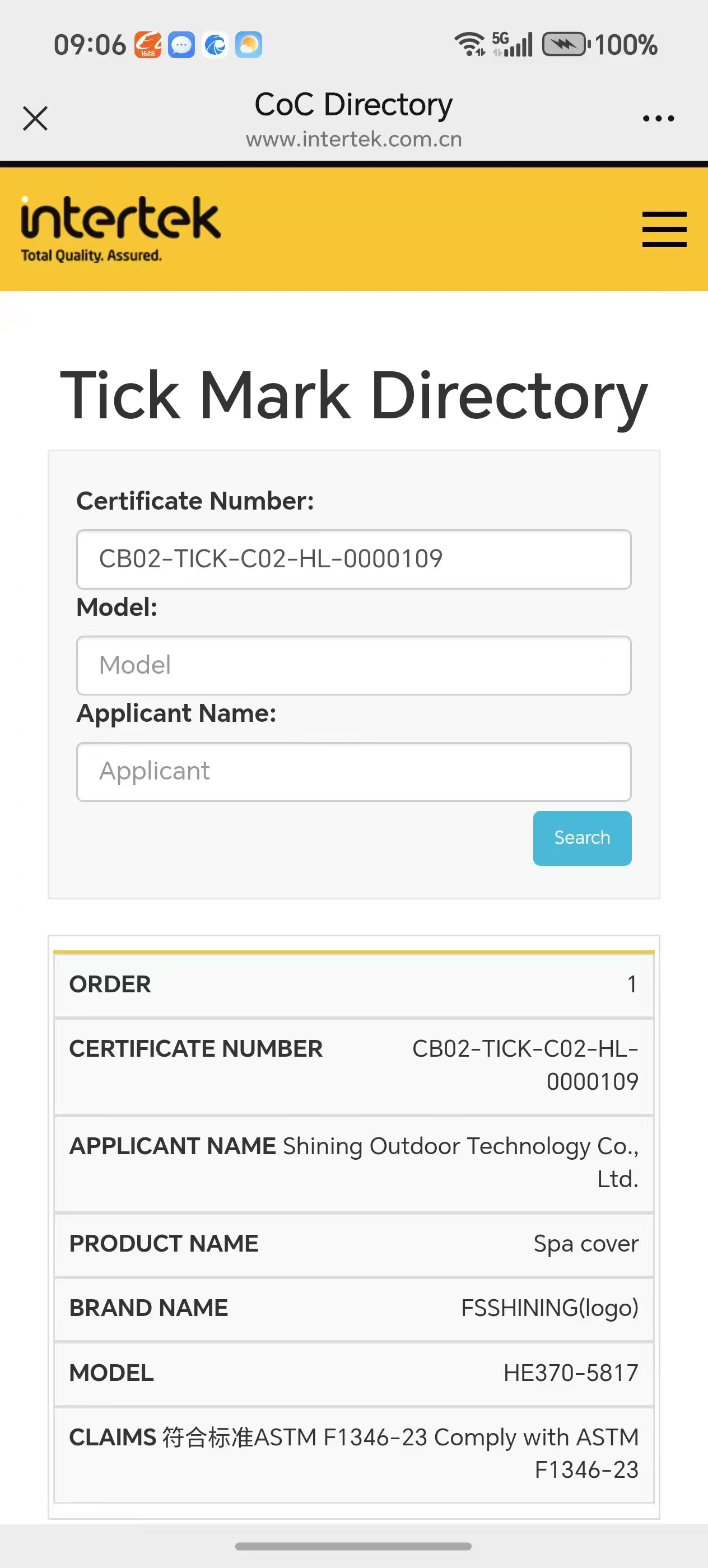

· Always Choose a Safety-Rated Cover (ASTM F1346 compliant).

· Select Locking/Clamping Mechanisms: Appropriate for your security needs.

· Use Wind Straps: In windy areas.

Fit & Seal

Precision Measurement

· Critical. Measure the spa shell's inside lip dimensions (length and width) at the widest points.

Skirt Design

· Standard Skirt: 3"-4" drop, suits most flush-top spas.

· Extended Skirt: 5"+ drop, needed for raised-tile spas.

· Tapered Skirt: Wider at the top, narrower at the bottom.

Seal Quality

· A well-fitting cover with a proper skirt creates a "vapor seal," trapping heat and humidity inside the spa.

Recommendation

· Measure Meticulously: Choose skirt style/length based on your spa's cabinet design.

Additional Features & Considerations

Lifters

· Essential for ease of use, match the lifter type to the cover's weight and size.

Vents

· Small vents near the hinge allow minimal air exchange to prevent condensation buildup.

Handle Quality

· Reinforced, durable handles are crucial for maneuvering heavy covers.

Warranty

· Reputable manufacturers offer warranties covering material defects and workmanship.

Climate

· Extreme Cold: Demands highest R-value (IMPA).

· High UV/Sunbelt Areas: Demand premium UV-resistant facing.

· Humid Areas: Demand flawless vapor barriers.

Cover Size/Weight

· Ensure you have the physical strength or assistance to handle the cover.

Purchasing Process & Avoiding Pitfalls

Know Your Spa

· Model, exact dimensions, cabinet type, any obstructions.

Set Your Priorities

· Rank insulation, longevity, safety, ease of use, budget.

Research Manufacturers

· Focus on companies specializing in spa covers, using quality materials, offering clear warranties, and allowing customization.

Get Detailed Quotes

· Specify core material, facing material, barrier system, R-value, safety rating, hinge type, reinforcement details, skirt type/length, warranty terms.

Beware of Low Prices

· Extremely cheap covers often use inferior materials, leading to rapid failure and higher long-term costs.

Confirm Customization

· Ensure the cover is made to your specific measurements.

Ask About Lead Time

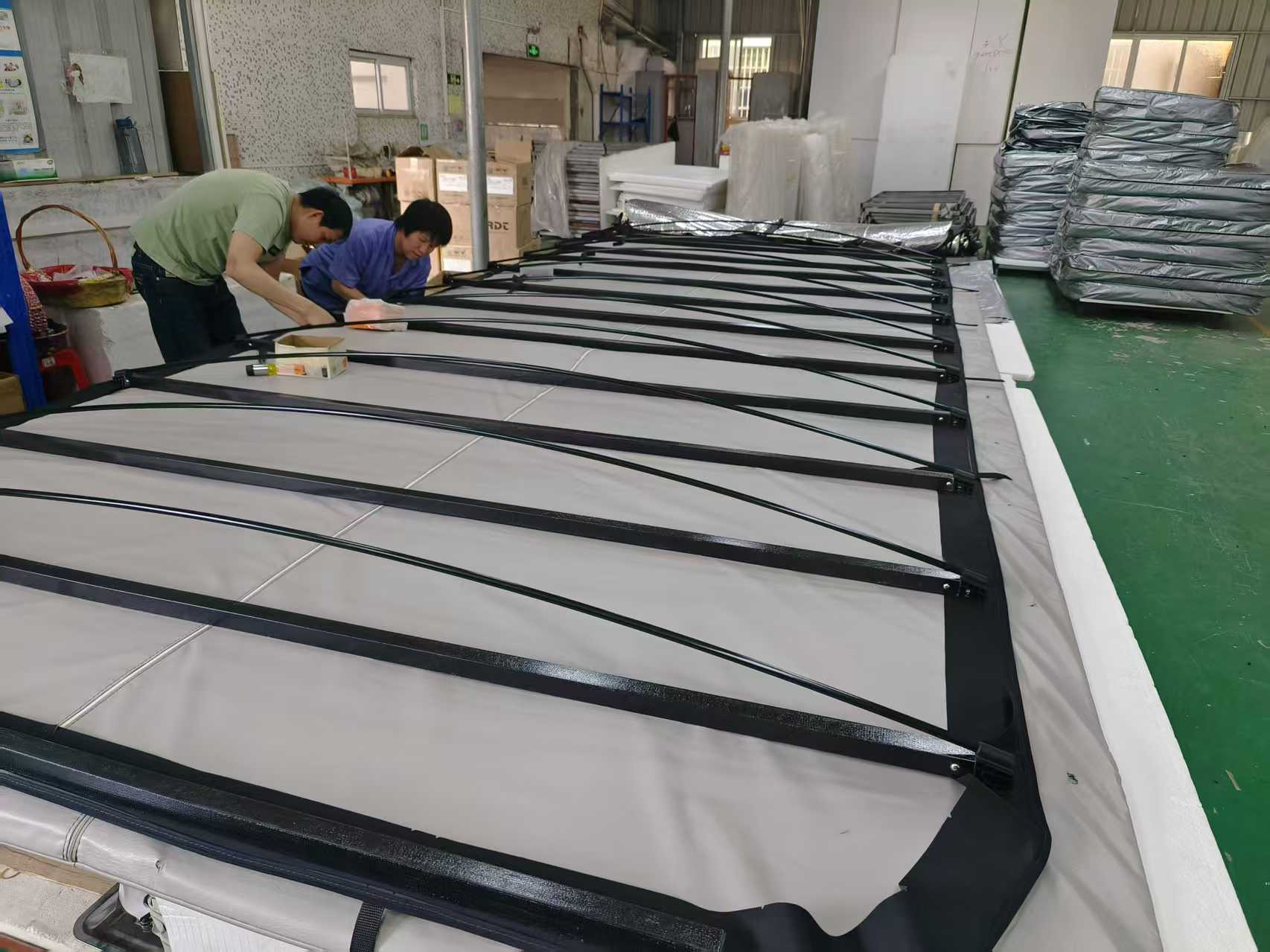

· Quality custom covers take time to manufacture (often 1-3 weeks).

Review Warranty

· Understand what's covered, for how long, and the claims process.

Shining SPA cover has been approved ASTM certificate for Europe and USA markets, even approved CEC Americian certificate. Our spa cover, swim spa cover, rollaway cover can guarantee the insulation.

Conclusion

Investing in a high-performance spa cover is a critical decision impacting your spa's operating costs, water quality, safety, and longevity. By prioritizing a precise fit, quality insulation core (XPS or IMPA), durable facing material (Reinforced Laminate or TPO), meticulously sealed vapor barrier, robust structural elements, and certified safety features, you ensure maximum heat retention, longevity, security, and overall value. The initial investment pays dividends over time through significant energy savings and extended lifespan.